Some of you are probably stuck at home because of covid19. Perhaps you are attempting to do a do-it-yourself project during this period. Or you are taking the time to clean and inspect your gun collection. In any case, I thought a little article on gun stock finishing might be of interest.

High grade custom guns usually have an oil finish applied to the stock. Production guns often have a polyurethane finish sprayed on. While that holds up great, it is difficult to re-finish a section on the stock without stripping the entire finish. It also is very bland and deadens the warmth and natural color of the wood. The stocks on most high end custom guns are usually finished with a hand rubbed oil finish. A good oil finish for gun stocks will bring out the natural color and 3D effect of the wood grain. It will hold up well in the field. And it is easy to touch up small areas on a stock and blend it back in with the existing finish. Most oil finishes are linseed or tung oil based and have added driers in it.

There are a ton of finishing products available. I’ve tried many of them, and have a closet full of products.

Many of them work just fine and I think it is important to stick with a procedure for a while and learn to work with it. While working in the old world, we primarily used a product named “Schaftoel”. I think it was a walnut oil. Until I came to America, I never even heard of filling the pores on a stock. Back then we applied the oil onto the stocks until a desired color was achieved. Then with cotton balls dipped in varnish we polished the stocks with a clear coat to give it some shine and protection. The results where never very satisfying and the cotton balls where suspect to spontaneous combustion.

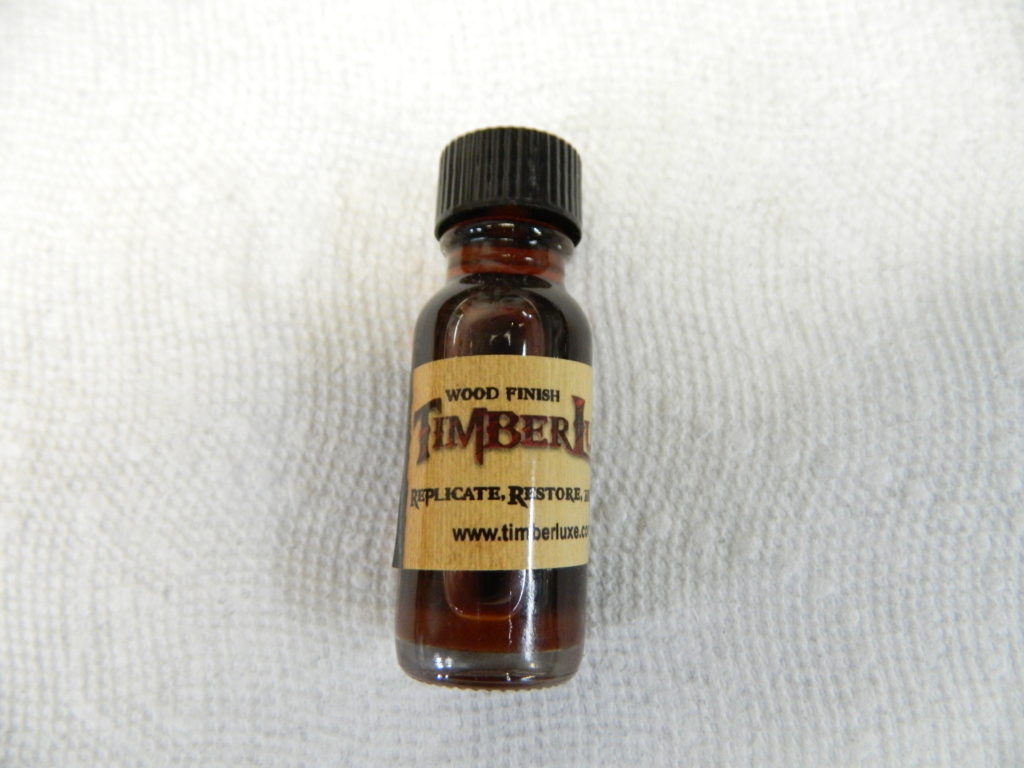

I use a wood sealer for the inside of the stocks. Currently the outside I completely finish with a product named TimberLuxe.

After sanding and whisker a stock up to 320 grit, I raise the pores and apply Timberluxe with a brush until the wood does not absorb it anymore. After at least a day of drying I fill the pores per wet sanding and with the same product. The oil and sanding mud is left to dry on the stock. A day later it can be sanded off, and the procedure is repeated if the pores are not completely filled. Once the pores are filled, I apply one coat of finish per day, rubbing it into the wood with the palm of my hand. At one stage the finish usually needs to be sanded back slightly again with 400 grit. Thereafter more coats are applied. After the stock sits around for a while, the pores tend to sink in slightly and I will give the stock a final sanding with 600 grit. After this more coats are applied until the finish feels smooth and silky to the touch. I find Timberluxe to be one of the easiest products to get great results with. And it seems to hold up very well over time.

To maintain a nice finish on on your rifle I would recommend to wipe the stock after use with a soft cloth. The finish should be occasionally nourished. A drop of boiled linseed oil on a cloth will do fine. I’ve found that guitar polish/cleaner that you may find in music stores works very well too. Careful with the checkering. A designated tooth brush works well to clean the checkering and it will benefit too from a very small amount of oil.