One of the advantages that you have when you order a rifle with us is that your gun is truly going to be built for you, and each rifle is a one of a kind. For example, we try our best to make each stock to the customers dimensions. Factories don’t have the flexibility to do that. To determine the customers stock dimensions, it is always best to meet in person. We have a fully adjustable try gun which aids us in establishing proper fit.

When making the stock, most custom gunsmiths depend totally on pre-made patterns which they use to copy the stock on pantograph machines. We also utilize a Hoenig pantograph machine and some patterns, but primarily the machine is used for the inletting and often just for roughing out of the outside contour. Depending on the stock, about up to 85 % of the inletting can be pre-carved on the machine and it saves a lot of time. The remaining inletting is done by hand with chisels and scrapers.

The picture above is of me working on a butt stock.

The outside dimensions on our stocks vary from client to client. Most of the time it takes me less time to shape the inlet stock by hand versus to alter the outside of a pattern or spend a lot of time on making a new pattern. So the outside of the stock is carved oversize on the machine, or sometimes left completely as a block.

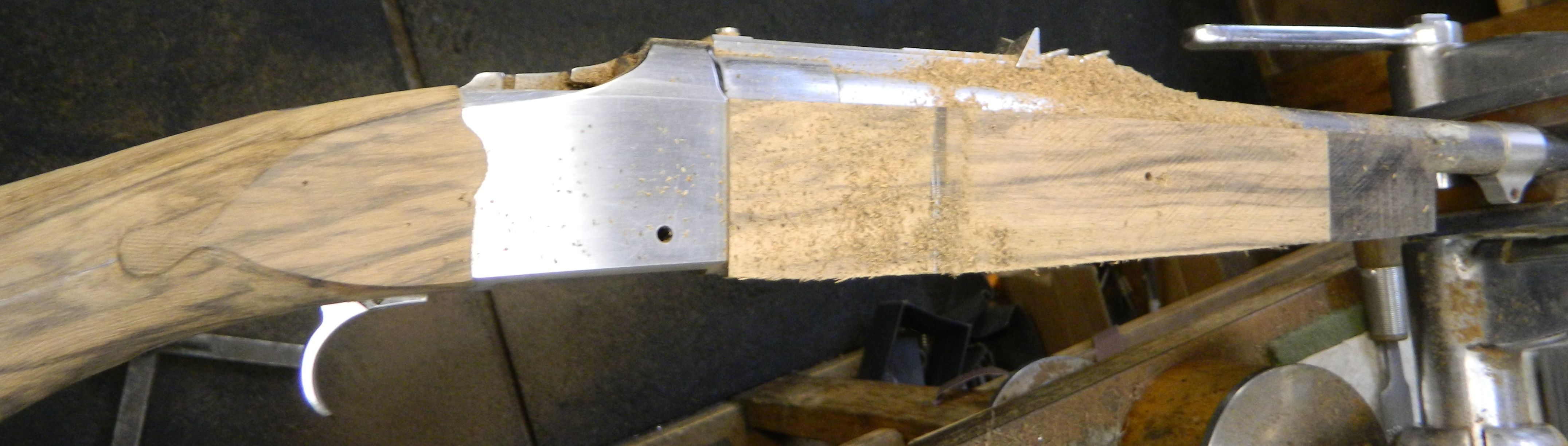

This picture is of the re-stocking of a vintage Holland & Holland Paradox. The metal is inlet and the stock is being shaped with hand tools.

The picture above is of the stocking of a custom Ruger #1 rifle.

The 2 pictures above are of the rough shaping of the Ruger stock.

Once everything is rough filed, I usually spend another full day to re-fine everything and to prepare the stock for the first sanding. The shaping of the stock is a lot of fun, a process that I enjoy very much. And my clients enjoy receiving pictures of their stock taking on it’s final form.