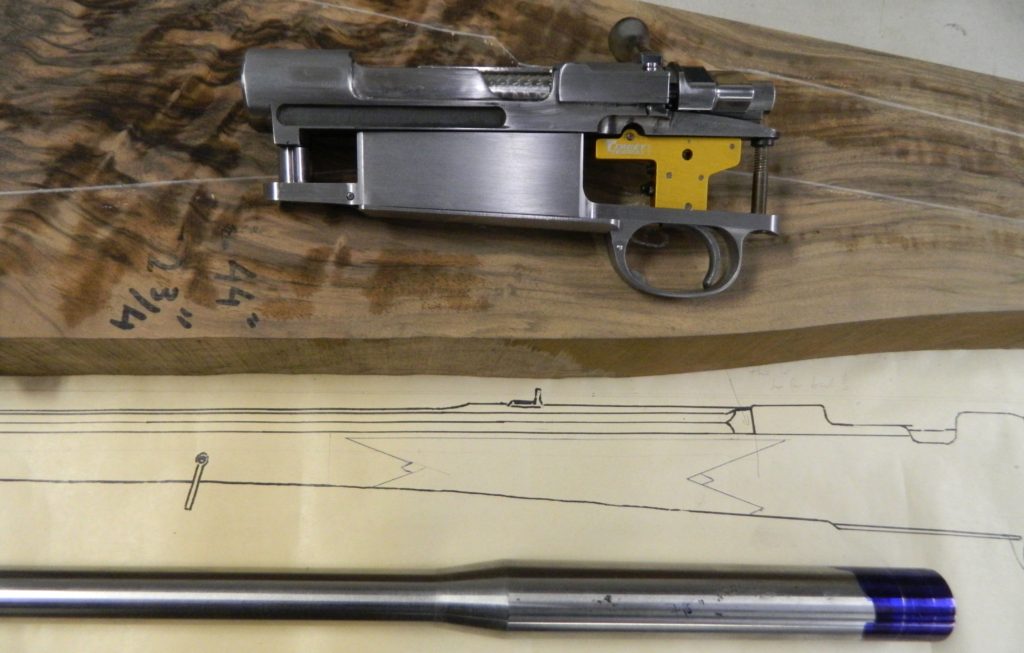

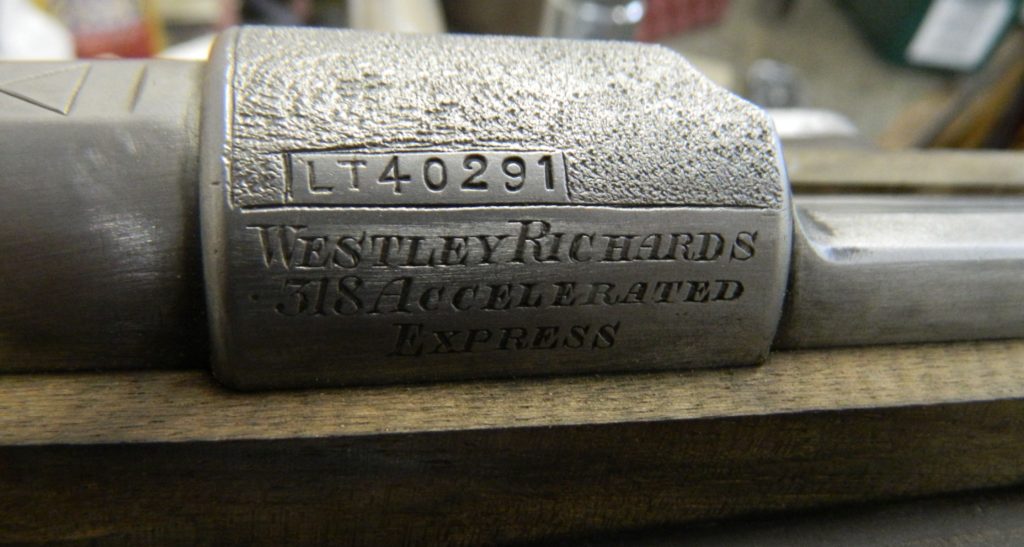

Once in a while I get inquiries to do a complete makeover of a vintage rifle. In this case my client had been offered a 1920 Westley & Richards rifle for sale, together with a new stock blank and a duplicated pattern stock. The original stock had been oil soaked and cracked and was completely worn down. The barrel had some corrosion on the inside, and the outside had a thick patina on the metal. Everything was in pretty rough shape. My client considered buying the rifle, then have me re-stock and re-store the rifle to original condition. Is it worth to do a project with a rifle gone that far? My advise was, yes, if it shoots well, and no, if the accuracy is bad from the start. If re-barreling would be required it would be smarter to build a custom rifle from scratch. The original proof marks would have been lost and at that time in my opinion the Westley Richards association would have been pretty minimalized.

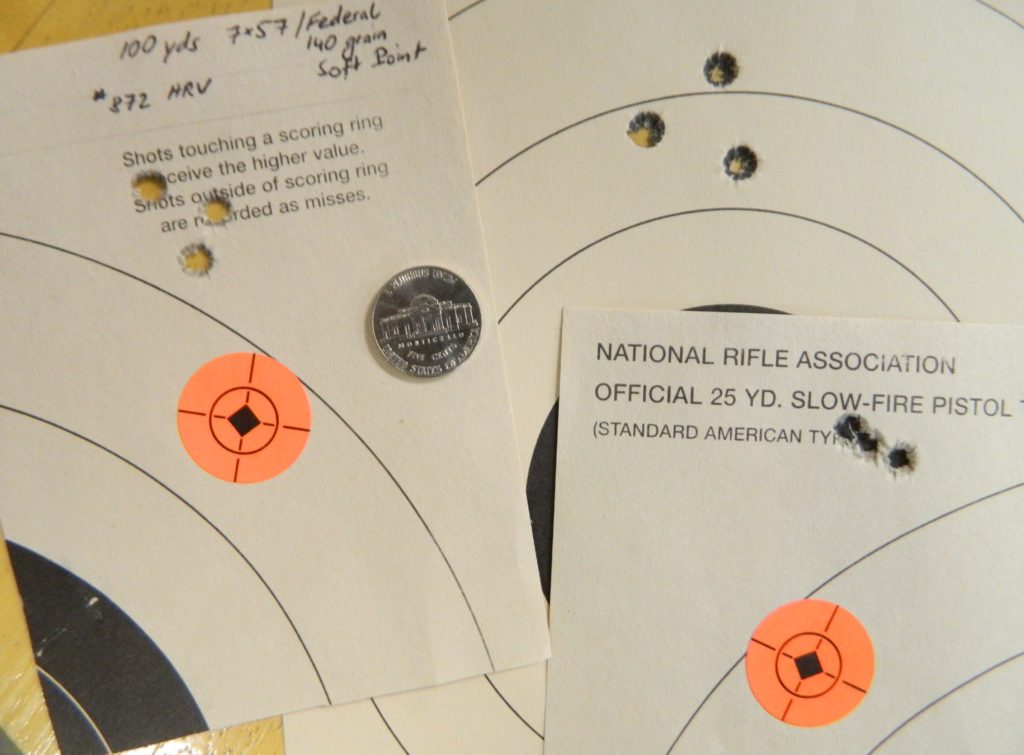

My client was given the opportunity to test fire the rifle before purchasing it, and low and behold, the accuracy was a very pleasant surprise. The decision to go ahead was made.

We expected having to re-cut the letterings on the rifle by an engraver. Bead blasting of the metal revealed however that the lettering was deep enough to be left alone.

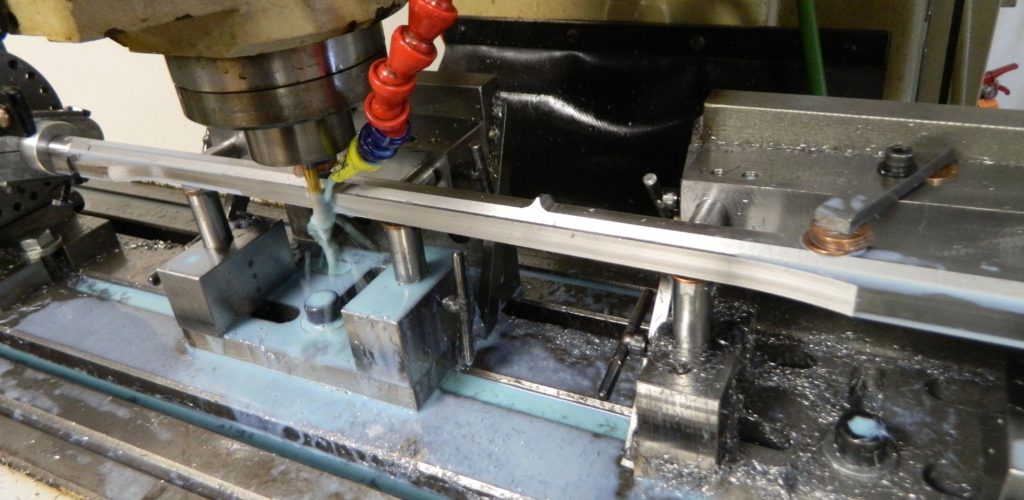

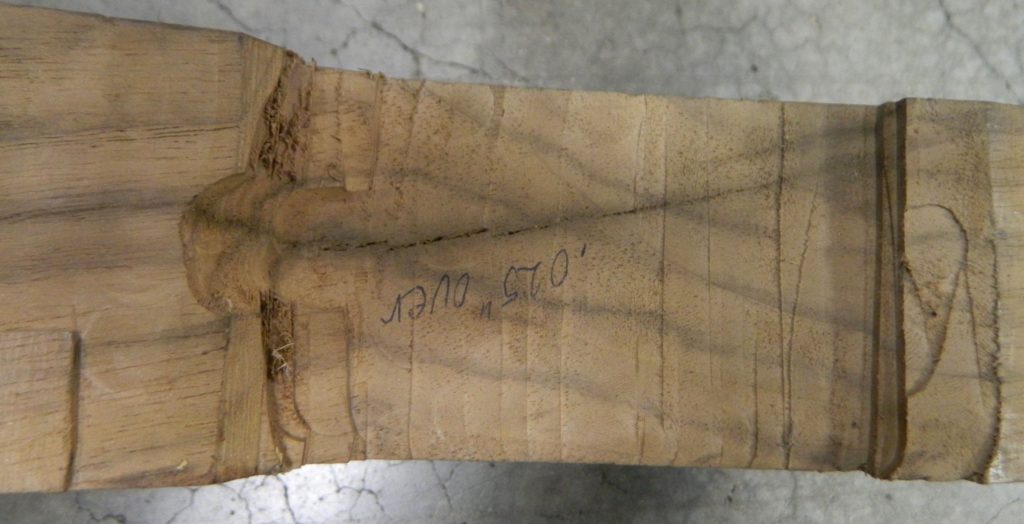

The stock was carved from the supplied pattern and it is very closely made to the original. I did add about 1″ of length of pull to the stock to accommodate my client better. On the original stock a horrible ventilated recoil pad had been installed. We assumed that the stock originally had a steel butt plate. I was able to locate a period correct trap door steel butt plate. New screws and a drill guide had to be made for the butt plate.

The original grip cap and diamond inlay on the forearm where used, but new screws had to be made and timed. A horn forearm tip was added to the stock.

The checkering of a vintage W&R rifle presents a further challenge and difficulty to the stock maker. Typically on those guns the rear borders of the grip checkering are the master lines and go over the top.

Here are a few pictures of the finished project. I made a period correct sling swivel stud and a new ivory front sight for the rifle as well. Some of the parts where then sent off for case color hardening and the barreled action was rust blued by my friend Stan Tabasco. I really had fun shooting this classic. The accuracy was impressive and dare I say, unusual for an old gun like this. The trigger was a typical Mauser 2 stage. We left the original trigger in the gun. But I blocked the first stage and changed it to a single stage trigger.

It always is wonderful when the client is able to pick up his gun in person. I truly hope that he is happy with my work and I hope the rifle will be a great companion and play an important role in his future adventures. There is a great sense of satisfaction to doing such a project, and I hope to get similar commissions in the future.

Here is a brief history of this rifle in my clients words:

“The rifle was built in 1920, sent to a British officer by the name of J. F. Dobson, who served served in India. No one knows how and/or when the rifle made its way to the hands of an unnamed professional hunter in Africa. Basil Bradbury, of Boone and Crockett fame and former editor of Peterson’s Hunting magazine, brought the rifle back from Africa. By this time, the stock had two cracks in it and the checkering around the pistol grip and foreend had been worn completely smooth. In March of 1993, Basil Bradbury gifted the rifle to my friend Jay Lesser, founder and former owner of Wyoming Professional Hunters and former Boone and Crockett member. Shortly thereafter, former shooting editor for Guns and Ammo magazine, Ross Seyfried, gave Jay a box of Nosler Partition 250 grain .338 bullets, which had been centerless ground to a diameter of .330 so that good hunting ammunition could be made for the old rifle. It should be noted this all happened before the internet and the wide distribution of Woodleigh Bullets, which the rifle currently shoots very well. I bought the rifle, including the Ross Seyfried Nosler bullets, a fine stock blank, a pattern stock, and RCBS loading dies from Jay in November of 2015. I promptly shot two 1.5 inch-100 yard-3 shot groups with the rifle, and delivered the rifle to Reto Buehler for resurrection. An elk hunt with Jay and the Ross Seyfried bullets is being planned for fall of 2021 or 2022”.