In the past years I’ve had several times the honor to create rifles that celebrate special occasions. A great project was a rifle I built for a father, commissioned by his son. The son has been successful in his career and wanted to give back to his dad. The dad had a modest background and could not have afforded a custom rifle. In the near future I’ll be building a great rifle for a gentleman, to the specifications of his late brother. Basically, the rifle his brother imagined owning, as a memory.

Two gentlemen contacted me a while ago. They had two vintage German 33-40 Mauser style actions and two beautifully matching stock blanks. The plan was to build 2 rifles in the style of the vintage Rigby rifles, caliber .275 Rigby. They had set out to have two identical open sighted rifles built, to commemorate their long friendship. Eventually there was more to this story, but I leave it at this. They could have gone directly to Rigby. But they went this route, knowing they wouldn’t get factory rifles, but guns that received very personal attention to details and a soul.

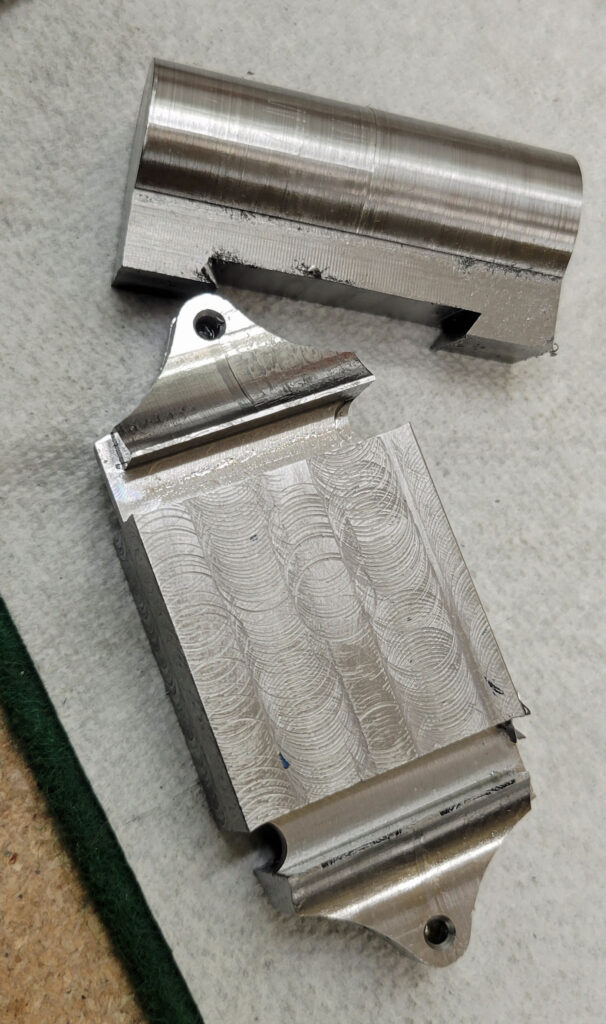

I started off with two Brux barrels and copied the barrel contour of a vintage Rigby rifle. Then I machined the front sight ramps, sight hoods, banded rear sight ramps and the unique Rigby style barrel sling swivel studs.

The actions got surface ground and the rear humps where removed. On an Obendorf Mauser I would have left the hump, but the 33-40’s have an odd styling and it is best removed. After truing the actions and the bolt face, new bolt handles got installed. Some of the old Rigby’s had flat shaped bolt handles. A feature important to my clients. The barrels got then fitted to the actions. Initially, we thought of altering the military triggers to single stage. I took liberty with that and added Timney triggers. It occurred to me, if Rigby would have had such fine triggers back in the day, they certainly would have used them.

The ramps etc. got fit and soldered to the barrels. After a clean-up, ready for stocking!

As I do often, the inletting was 80% carved on a Hoenig pantograph machine, the outside I shaped by hand from the block. On one-of-a-kind stock shapes I don’t waste time fiddling with the pattern. I leave that to amateurs:-) Like on the vintage Rigby’s we decided to leave the cheek piece off.

In the picture above, the stocks are roughed out. In this stage, another day of labor is performed on each stock to re-fine everything before sanding. That extra day makes all the difference in the overall quality. I recently looked at the engravings of a double rifle performed by a well-known engraver. The engravings where very good, but if he had spent one more day on refinements, it would have been great. But as he left it, the scrolls where flat and unfinished.

Sanding, finishing and checkering was next on the program. I made the stocks matching as close as I could. One of the two stocks is shorter by 1/2″ to accommodate the owner.

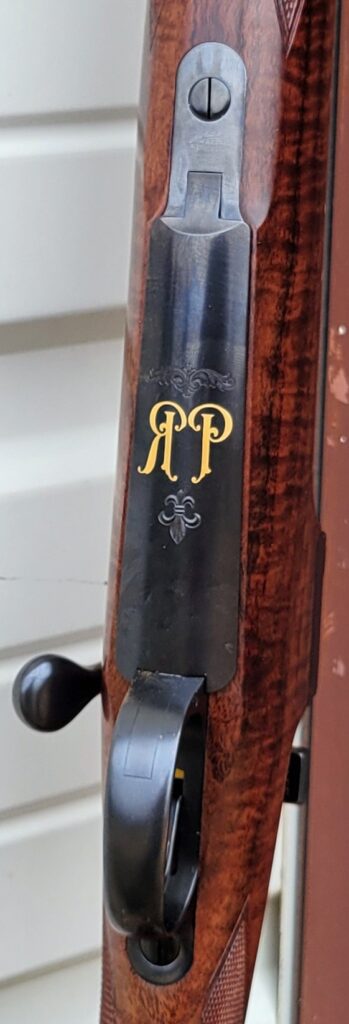

The metal was prepared for finishing. Parts were sent off to Jesse Kaufman for engraving. A special thank you to Jesse; his recommendation had led to this commission. Then, all left was the finishing, final assembly and final test firing.

And there it is, the finished product. What an honor it has been to have been part of this.